CT Trading Products

WPC Doors in Chennai

WPC doors are a perfect choice for home and office interiors in Chennai, combining the beauty of wood with the durability of plastic. These doors are resistant to water, termites, and warping, ensuring long-lasting performance with minimal maintenance. Available in a range of designs and finishes, they enhance the style and functionality of any space.

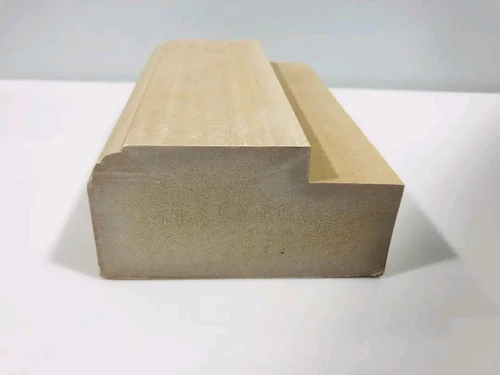

WPC doors: WPC- Wood Plastic Composite.

These types of doors are a combination of wood fibers or wood flour and thermoplastics such as PVC

Wood fibers

The wood fibers are the fundamental structure of the wood. They are mixed with plastics in the manufacturing process of WPC (Wood Plastic Composite), resulting in a composite material that has the appearance of wood along with enhanced durability and resistance to moisture.

Thermoplastics

They are a type of polymer that becomes pliable when it is subjected to heat and gets solidified when cooled.

Why thermoplastics are used in the production of WPC doors?

Moldability/customization:

Thermoplastics can be melted and molded into different shapes, allowing for flexibility and achieving specific performance characteristics that enhance customization based on required applications.

Recyclability/durability:

- Both wood fibers and thermoplastics are recyclable, making WPC doors a sustainable option.

- The thermoplastics enhance the durability of the WPC door by providing resistance to moisture, and termite control.

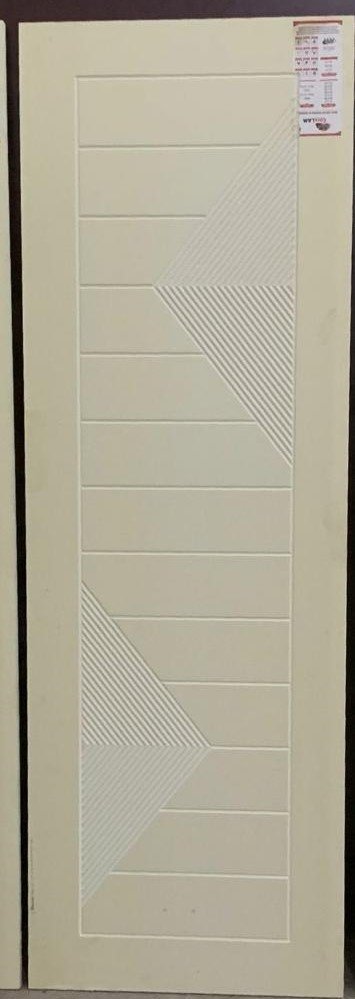

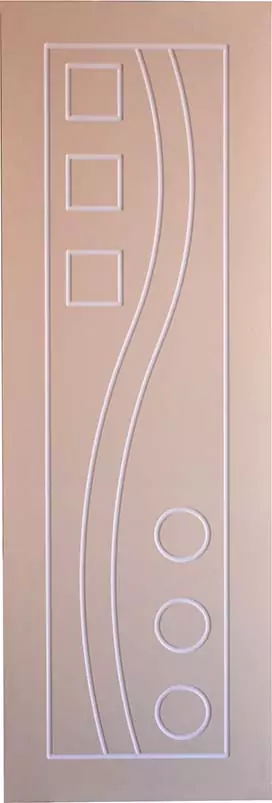

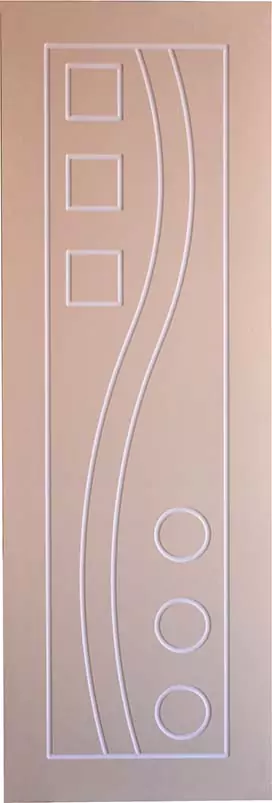

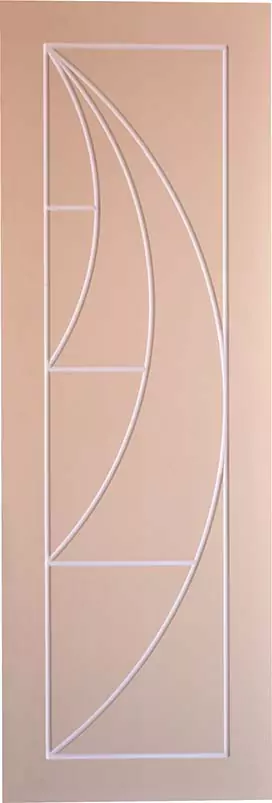

Top Selling WPC Door Designs

Our WPC door designs

How do WPC doors differ from Solid wood doors?

WPC door

- Construction: WPC (Wood Plastic Composite) is a combined product of wood fibers and thermoplastics, resulting in dual achievement that includes durability and wood-like appearance.

- Moisture resistant: WPC (Wood Plastic Composite) is resistant to moisture making it an ideal option for areas which is prone to humidity or direct water exposure.

- Durability: WPC (Wood Plastic Composite Doors) doors are resistant to termites. They require less maintenance when compared to solid wood doors.

- Customization/ insulation: The presence of thermoplastics in the combination, offers design versatility. It provides decent insulation but it cannot be matched with the insulation ability of solid wood doors.

Solid wood doors:

- Construction: Constructed in such a way that there are no hollow spaces in its core enhancing its durability.

- Moisture-resistant: They are susceptible to water-related issues when compared to WPC (Wood Plastic Composite) doors and solid wood doors require more maintenance to avoid warping.

- Durability: More durable due to its solid construction.

- Aesthetics/ insulation: It provides high insulation when compared to WPC ((Wood Plastic Composite) doors and gives an aesthetically appealing look.

Difference between Durability and Moisture- resistance?

“ A durable material may or may not be moisture-resistant, depending on its composition”

- Durability: The ability of a material to withstand high pressure.

- Moisture-resistant: Material’s ability to withstand moisture.

WPC Doors Technical Specifications

| S.No | Performance Characteristics | Criteria | Test Method | Specification Requirements ( IS 15931 : 2012 ) |

| 1 | Dimensions & Squareness Test | a) Average Height | As per IS :4020 ( Part 2 & 3) |

a) +3 to -0 mm |

| b) Average Width | b) +3 to -0 mm | |||

| c) Thickness, mm | c) +2 to -0 mm | |||

| d) Difference in length of diagonal, | d) ≤3 mm | |||

| e) Maximum variation in thickness between 2 points, | e) 0.2 mm | |||

| 2 | Impact Indentation Test | a) Appearance : Cracking & tearing was observed | As per IS : 4020 (Part 5 ) |

a) Satisfactory |

| b) Max Depth of depression, mm | b) 0.3 mm Max | |||

| 3 | Edge Loading Test | a) Deflection after 15 minutes in mm under load application | As per IS : 4020 (Part 7 ) |

a) 8 mm Max |

| b) Residual deflection | b) 0.7 mm Max | |||

| 4 | Shock Resistance Test | Soft & light body impact test observations for any visible damage after 25 blows on each side | As per IS : 4020 (Part 8) |

No visible damage |

| 5 | Buckling Resistance Test | a) Appearance – Observation for deterioration | As per IS : 4020 (Part 9) |

a) No Deterioration |

| b) Residual deflection, 30min after removal of load, in mm | 5 mm Max | |||

| 6 | Misuse Test | Observed for any permanent deformation affecting normal | As per IS : 4020 (Part 11) |

No permanent Deformation |

| 7 | Slamming Test | For any damage at the end of 50 successive impacts | As per IS : 4020 (Part 10) |

No visible Damage |

| 8 | Screw Withdrawal Resistance Test | i) Face Direction & ii) Edge Direction | As per IS : 4020 (Part 16) |

in 1000 N |

Key Advantages of WPC Doors

| WPC DOOR Advantages | |

| 100% Eco-friendly product | Maintenance free |

| Solid door structure with absolute strength | No Paint & No Polish required |

| Best to stand with high moisture and humidity level | Surface decoration of WPC DOOR |

| High tensile strength | Can treated with HPL lamination |

| High screw holding capacity | Best routed with CNC router |

| Better maintainability | Can be applied with PVC foil lamination on Vacuum press |

| Can be processed like natural wood, MDF, Plywood on any panel processing machine | PVC edge bending can be applied nicely |

| Corrosion resistance | Paper lamination can be done easily |

| Nontoxic and borer free | PU coating and UV coating can be done |

| Easy to cut and saves tooling life almost 30 % than MDF and particle boards | Printing can be done with high resolution |

| Anti-abrasiveness | Surface can be painted |

| High temperature resistance | Foil transfer mechanism |

| Perfect surface finishing | Moldings can be applied |

| Accuracy in dimensions | Light weight structure |

Applications of WPC doors:

Residential Use:

In homes, WPC doors are commonly used for interior applications such as bedroom doors, bathroom doors, closet doors, and kitchen cabinet doors. Homeowners appreciate their durability, resistance to moisture, and ease of maintenance. Unlike traditional wooden doors, WPC doors are less prone to warping, cracking, or swelling when exposed to humidity or moisture, making them ideal for use in areas with fluctuating environmental conditions.

Commercial Use:

In commercial buildings such as offices, hotels, restaurants, and retail stores, WPC doors are used for both interior and exterior applications. Interior doors in offices and commercial spaces need to withstand frequent use while maintaining their aesthetic appeal. WPC doors offer a sleek and modern look, making them suitable for modern office environments. Additionally, their resistance to wear and tear makes them ideal for high-traffic areas like corridors and entranceways.

Educational Institutions:

Schools, colleges, and universities often choose WPC doors for their classrooms, laboratories, administrative offices, and common areas. These doors can endure the rigors of daily use in educational settings while providing a clean and professional appearance. Moreover, their resistance to moisture and easy-to-clean surface makes them suitable for maintaining hygienic environments in schools and healthcare facilities.

Healthcare Facilities:

Hospitals, clinics, laboratories, and other healthcare facilities require doors that can withstand frequent cleaning and disinfection. WPC doors are resistant to moisture and microbial growth, making them suitable for use in healthcare environments where cleanliness and infection control are paramount. They are also easy to sanitize, helping to maintain a hygienic environment and minimize the risk of cross-contamination.

Hospitality Industry:

In hotels, resorts, restaurants, and other hospitality establishments, WPC doors are used for interior applications such as guest room doors, bathroom doors, and corridor doors. These doors contribute to the overall ambiance of the space, offering a combination of aesthetics and durability. Additionally, their resistance to moisture makes them suitable for use in humid environments like bathrooms and swimming pool areas.

Retail Spaces:

WPC doors are commonly found in retail stores, shopping malls, and commercial outlets. They serve as entrance doors, interior doors, and partition doors, providing a clean and modern look while withstanding the demands of daily use in a commercial environment. Their durability and low maintenance requirements make them a practical choice for retail spaces where appearance and functionality are important considerations.

Exterior Applications:

While less common than interior applications, WPC doors can also be used for exterior doors in residential and commercial buildings. They offer resistance to weathering, moisture, and insects, making them suitable for use as front doors, patio doors, and balcony doors. Additionally, they require minimal maintenance compared to traditional wooden doors, making them an attractive option for homeowners and property managers.

Score Card:

- Round 1: WPC doors knock down Solid wood doors with their moisture-resistant ability and less maintenance.

- Round 2: Solid wood doors knock down solid wood doors with their durability.

- Round 3: Draws for a place where both doors can be purchased according to our preferences.

Chorpa groups: WPC doors, where elegance meets durability, securing your space with timeless style

Chopra Group stands as the epitome of excellence in the manufacturing of WPC doors in Chennai. With a commitment to quality, innovation, and precision, we redefine spaces with doors that transcend expectations. Our WPC (Wood Plastic Composite) provides aesthetic appeal with robust functionality, crafting meticulous craftwork. Utilizing cutting-edge technology and premium materials, each door is a testament to durability and timeless design.

Committed to environmental responsibility, our manufacturing processes adhere to sustainable practices. Choose Chopra Groups for doors that not only elevate your surroundings but also reflect our unwavering dedication to delivering the best in WPC door solutions, where quality meets innovation in every intricate detail