CT Trading Products

The Best Shuttering Plywood for Constructions

Embrace the exquisite beauty of Shuttering Plywood, transforming your space into a haven of elegance.

Back to the past: the history behind discovery/ invention:

The history of shuttering plywood is closely correlated with the history of plywood which starts from the mid-19th century when there was high demand for the construction of buildings. Shuttering plywood is mainly used for interior purposes where durability is the important factor rather than an appealing look.

Question pops up:

Does shuttering plywood give an appealing look? Shuttering plywood is mainly used for the construction of concrete structures. So its main usage is structural support rather than an appealing look.

Popularity rate:

Shuttering plywood is widely used in the field of construction of concentre structures, not steel framed buildings

Shuttering plywood

Shuttering plywood is a term quite commonly used in the construction industry. The shuttering process – pouring the concrete into moulds – cannot happen without using shuttering plywood. This is a kind of plywood which is designed in a way to prevent concrete from coming out of the mould. This material is not used for aesthetic purposes, but to hold concrete till it densifies to form a solid structure. It is weather resistant and doesn’t stick to the concrete itself.

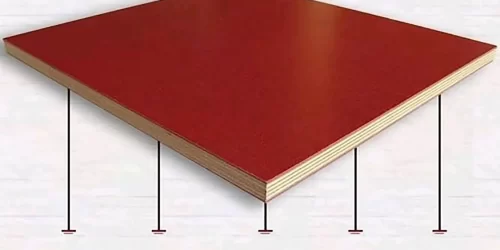

It is like any other plywood or wooden panel, created using thin veneers layered on top of each other and glued together. Veneers are laid in such a way that their grains run perpendicular to each other. If constructed properly, they have high strength. This kind of construction ensures that they are high in strength and would not split when used for construction. Shuttering plywood manufacturers provide these materials in different thickness and sizes to meet different construction demands.

As understood, shuttering plywood is used for outdoor applications. So, they are naturally water resistant, do not warp or rot. Also, the glue used to make the shuttering plywood is resistant to water penetration to ensure strength and durability. This kind of plywood can be reused, albeit with some precautions. They should be cleaned carefully and stored in a cool, dry place. Shuttering plywood can also have a smooth and attractive outer veneer of higher quality than those used in the inside layers. This type of surface is usually needed for clean and attractive construction where aesthetic matters the most. However, plywood requires regular sanding and finishing after every use. Shuttering plywood which doesn’t feature a clean surface is not meant for aesthetic purposes. It is less expensive than the polished ones.

Construction professionals use temporary wood or metal supports to hold shuttering plywood in place. Once the plywood is in place, concrete is poured into the mould to give it the desired shape. 12mm Shuttering ply is quite popular in the construction industry for moulding concrete.

Strength- Solid wood can be incredibly strong for construction purposes; however, it is not as strong as Plywood. With Plywood, there are minimum issues that can generally occur with natural wood when used in construction. Because of the cross-grained structure of the Plywood, the strength will be evenly distributed. Solid wood can be strong with the use of grain. When Plywood is installed with veneers and phenolic adhesives, it can be even stronger..Durable – When compared to solid wood, Plywood can be more durable and last longer. Plywood has uniform strength as it uses grains, veneers, and adhesives. Plywood is mostly used in construction because it can be great at resisting any sharp blows. It can also withstand different kinds of in-service abuse and wear and tear. Plywood is a durable engineered wood product that will not need repairs if maintenance for a long time.

Lightweight – Along with its strength and durability, Plywood is also lightweight and easy to work with. It is much lighter when compared to solid wood and can be easily installed during construction work. Plywood is great for building furniture and for other commercial applications. Builders have found that shuttering Plywood is easier to use during commercial operations as it is more versatile and workable. Plywood for commercial operations is great for using on curved surfaces. Solid wood can be hard to work with because it creates uneven edges with rough and poor furnishings. Plywood is great for curved surfaces as it creates more even furnishings. If you have a commercial project coming up and are looking for shuttering Plywood, Core Decore can offer high-quality and reasonable Plywood

Applications of shuttering plywood

- Retaining wall: For supporting concentre walls because of its durability.

- Bridge and tunnel construction: Employed in building framework as it demands strength rather than an appealing look.

Benefits of shuttering plywood:

- This plywood can withstand wet concrete walls

- Reusable as they are can be used for multiple purposes

- Consistent quality

| SHUTTERING PLYWOOD 30KG,35KG | |||||||||||

| SIZES | THICKNESS | ||||||||||

| 8X4 | 12MM | ||||||||||