C. T Trading Products

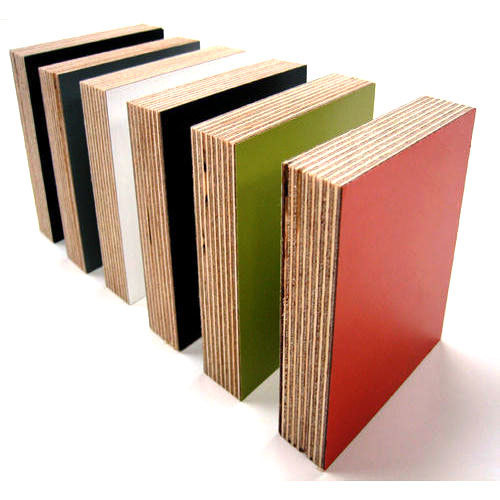

A Durable and Cost-Effective Prelaminated Plywood

Embrace the exquisite beauty of Prelaminated Plywood, transforming your space into a haven of elegance.

Back to the past: The history behind discovery/ invention:

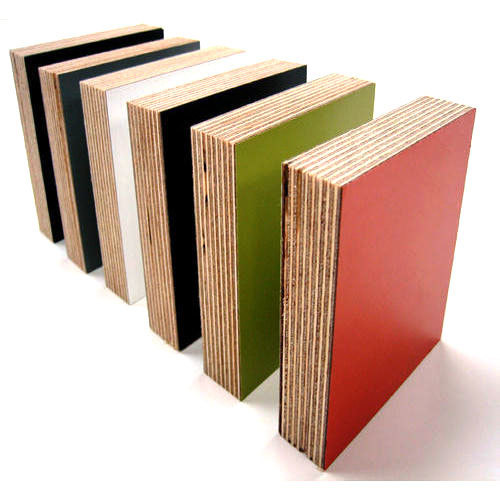

Plywood correlated with laminates ruling the world for the appealing look they radiate. Plywood is manufactured by gluing multiple layers of plywood together in a perpendicular direction, these laminates are placed over the plywood to enhance the aesthetic look radiated by the plywood. With the help of technological advancement, the aesthetic vibe is enhanced by laminating plywood with some other materials. As a whole, these materials are called laminates which are placed over the plywood to enhance the appealing look of the plywood.

Question pops

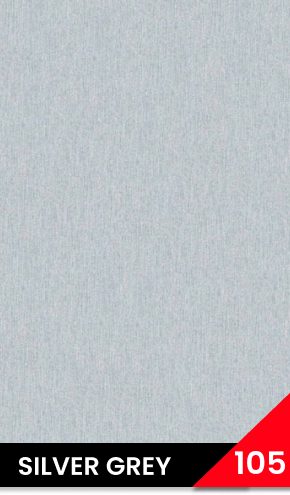

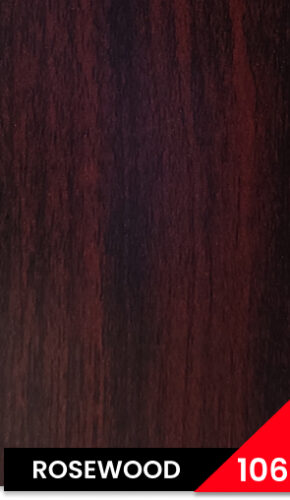

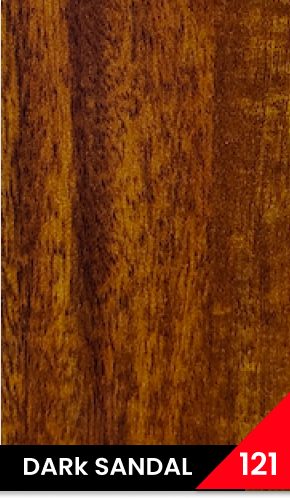

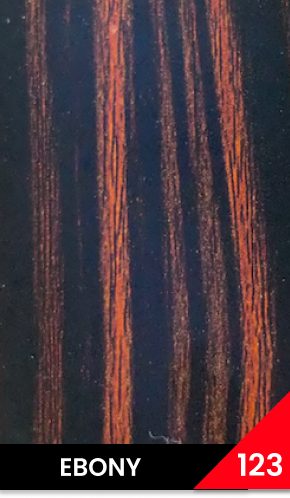

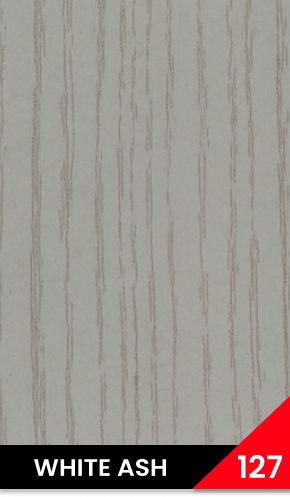

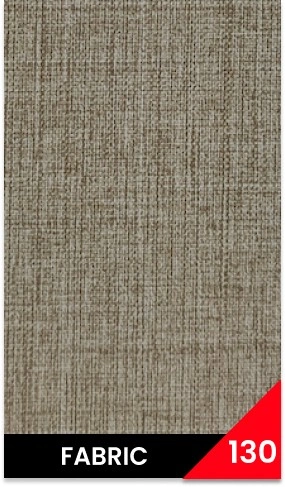

What makes pre-laminated plywood unique? The pre-laminated plywood offers customers multiple customizable options which allow customers to choose their desired option between multiple patterns, and colors.

Popularity rate

pre-laminated plywood is widely used in customizing our house according to our desired options as it comes in different patterns and multiple vibrant colors, making it an ideal option for radiating an appealing vibe that is both modern as well as satisfactory.

Chopra's pre-laminated plywood: From home decor to school desk decor:

Chopra’s pre-laminated plywood comes in multiple classy colors and unique patterns opening up wide options for customers to choose their desired ones. These pre-laminated plywoods are also customizable according to the customer’s preferences at our place. Not only pre-laminated plywood, plywood sheets are also available for customizing their plywood according to the customer’s preferences.

Applications of pre-laminated plywood:

- Interior decor: It's ruling the interior decor industry with vibrant patterns and colors.

- Educational institutions: Most of educational institutions prefer pre-laminated plywood for their furniture as it gives a comfortable vibe.

Benefits of pre-laminated plywood:

- The significant benefit of pre-laminated plywood is the variety of options it provides to customers and the appealing look that is radiated through its patterns.

- At the same time, it retains the durability and structural integrity of plywood.

Thicker = Stronger

Softwood = weaker

100% hardwood = even more stronger

Heavier = Stronger

Light-weight = weaker

Hardwood = stronger

Prelaminated Plywood Sheets:

A lot of time, cost and effort that goes into manually gluing laminates over plywood can be prevented by using prelaminated plywood sheets. However, you won’t have as much choice as you get in decorative laminates when you go for prelaminated plywood sheets.

What customers must also understand is that there’s a difference between prelaminated particle boards and laminated plywood. Most of the trendy ready-made furniture is made from pre-laminated particle boards or prelaminated MDF( Medium-density fibreboards) and not from laminated plywood. Not only is such furniture of poor quality and strength but also has a short life. So, if you prefer furniture that lasts a lifetime, go for Prelaminated plywoods.

| MELAMINE PLYWOOD | |||||||||||

| SIZES | THICKNESS | ||||||||||

| 8X4 | 17MM | ||||||||||

| 11MM | |||||||||||

| 8MM | |||||||||||

| 5MM | |||||||||||