CT Trading Products

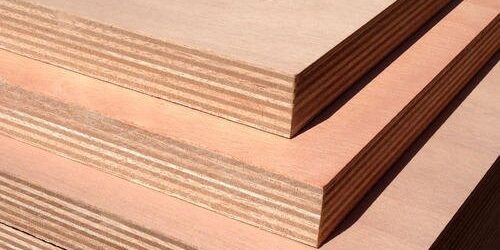

We are a wholesaler of BWR grade plywood

Embrace the exquisite beauty of BWR Grade Plywood, transforming your space into a haven of elegance.

Back to the past: The history behind discovery/ invention:

Boiling water-resistant plywood traces back to the mid-20th century which had witnessed huge advancements in technologies for wood manufacturing and the usage of formaldehyde and other advanced manufacturing techniques has led to the invention of much-advanced plywood such as BWR plywood- boiling water-resistant plywood.

Question pops?

What makes BWR plywood and MR plywood different, both can resist water to some extent but they are used in different applications according to our requirements. Both BWR and MR plywood cannot be used in areas that are frequently exposed to water or have constant water contact. But BWR plywood is more efficient than MR plywood as it has high water-resistant quality compared to MR plywood.

Popularity rate:

BWR plywoods are widely used in construction and furniture industries where humidity level is high.

Chopra’s BWR plywood- defying moisture with durability:

This Chopra plywood is tough and long-lasting. It can handle boiling water and keeps away borers. It's made using advanced technology that presses it tightly and ensures smooth edges. Chopra has ascended the throne of “ best plywood manufacturers” with its excellent customer services and durable products that exceeds the customer’s expectations with its intensive properties such as load bearing capacity and durability.

Applications of BWR plywood:

- Interior partitions: BWR plywoods are used in interior partitions where there is occasional exposure to moisture

- False ceiling: it requires the need for moisture resistance.

Benefits of BWR plywood:

- Zero core gaps: core gaps up to 1- 2mm don't affect the structural integrity of plywood but more than that will affect the structure of plywood leading to warping. BWR plywood has zero core gaps.

- Resistant to insects and termites: BWR plywood provides additional protection against decay.

| BWR GRADE PLYWOOD | |||||||||||

| SIZES | THICKNESS | ||||||||||

| 8X4 | 19MM | ||||||||||

| 7X4 | 16MM | ||||||||||

| 6X4 | 12MM | ||||||||||

| 8X3 | 9MM | ||||||||||

| 7X3 | 6MM | ||||||||||

| 6X3 | |||||||||||